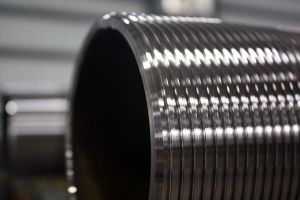

Tex-Isle, Inc. is committed to providing services and products to our customers that support our mission to be an industry leader in environmental performance. Our commitment extends beyond mere compliance with environmental laws and regulations and builds on our current success in achieving superior low-carbon performance for our steel pipe products.

Tex-Isle, Inc.'s environmental performance is enhanced by sourcing low-carbon steel and adopting best practices, including using recycled steel, using electric arc furnace technology, near 100% fully electric facilities, and proximity to our raw materials supplier, and our customers. Tex-Isle, Inc. will continually assess opportunities for further improvements to benefit our customers, our community, and our environment.